Precision-Made. Performance-Tested. Built to Last.

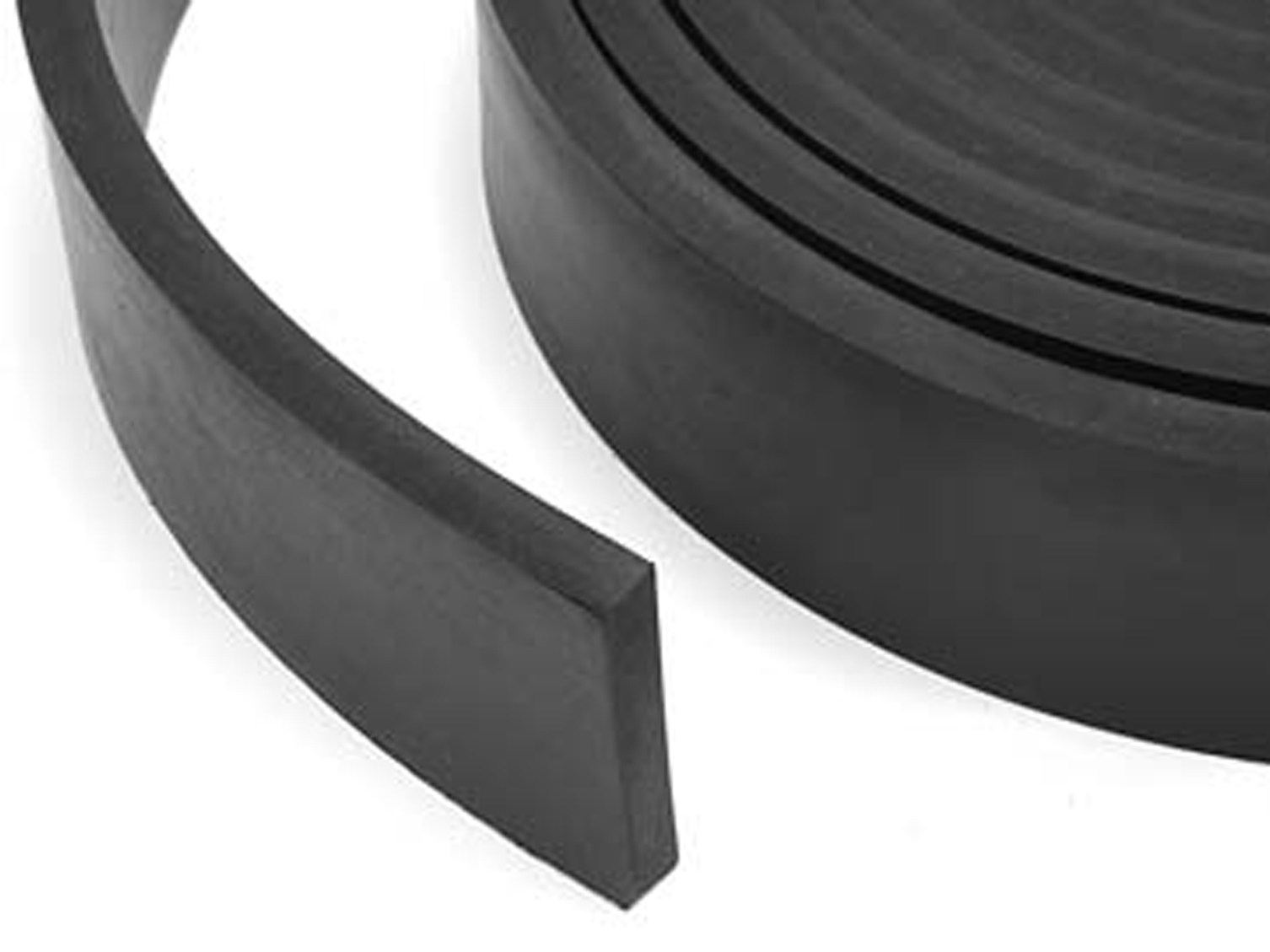

At Elplasto Innovations, we specialize in the production of high-quality EPDM (Ethylene Propylene Diene Monomer) rubber profiles using advanced Continuous Vulcanization (CV) line technology. With in-house capability to produce both solid and sponge profiles, we deliver reliable sealing, insulation, and vibration control solutions for diverse industrial needs.

Our CV Line setup enables fast production, tight dimensional tolerances, and superior physical performance — ensuring your rubber profiles are ready to meet demanding real-world conditions.

Why Our EPDM Extrusions Stand Out

Advanced CV Line Production

Unlike traditional hot-air extrusion, our CV Line uses microwave, hot-air systems for inline curing. This ensures:

- Smooth, consistent surface finishes

- Enhanced tensile strength and elasticity

- Improved compression recovery

Custom Sizes Up to 100mm

We can extrude profiles with cross-sectional widths up to 100mm, covering both small, intricate designs and larger industrial sealing profiles.

Solid & Sponge Variants

Choose from:

- Solid EPDM profiles for robust sealing, structural support, and vibration dampening

- Sponge EPDM profiles for compressible, lightweight sealing where flexibility is key

Engineered Accuracy

Our extrusion process is backed by automated controls, inline inspection, and an in-house R&D team that ensures your designs are precisely manufactured every time.

Profile Types – Custom and Standard Shapes

We offer a wide range of standard and fully custom extrusion shapes, including:

- Simple Sections

- Round, Square, Rectangular, Flat Strips

- Tube & Cord profiles

- Specialty Seals

- D-shape, P-shape, E-shape, T-seal, L-seal

- Bulb seals, Lip seals, Hollow sections

- U-channels & Edge Protectors

- For glass, sheet metal, panel edges, and doors

- Glazing Gaskets & Rubber Beads

- Ideal for window systems, curtain walls, and partitions

- Custom Cross-Sections

- Manufactured from your CAD drawings, physical samples, or application sketches

Technical Specifications of EPDM Rubber

| Property | Solid EPDM | Sponge EPDM |

|---|---|---|

| Hardness | 40 – 80 Shore A | 30 – 70 Shore OO |

| Tensile Strength | ≥ 7 MPa | ≥ 2 MPa |

| Elongation at Break | ≥ 300% | ≥ 150% |

| Compression Set (22h @ 70°C) | ≤ 25% | ≤ 30% |

| Density | 1.15 – 1.50 g/cm³ | 0.4 – 0.9 g/cm³ |

| Temperature Range | -40°C to +120°C (up to 150°C short-term) | -40°C to +100°C |

| UV/Ozone/Weather Resistance | Excellent | Excellent |

| Electrical Insulation | Very Good | Good |

| Water Absorption | Low | Low |

| Shelf Life | 5–10 years (if stored properly) | 3–5 years |

Applications Across Industries

Our EPDM profiles are trusted by OEMs, industrial equipment manufacturers, and infrastructure developers in applications such as:

- Construction & Architecture

- Door/window gaskets, curtain wall seals, façade expansion joints

- HVAC & Refrigeration

- Ducting seals, thermal insulation strips

- Electrical & Enclosure Systems

- Cabinet gaskets, dust and moisture seals

- Marine & Railway

- Hatch seals, buffer pads, weather strips

- Machinery & Equipment

- Vibration dampers, protective covers, anti-slip components

- Solar & Renewable Energy

- Panel frame seals, junction box gaskets

Prototyping and Mass Production

We understand that great products begin with smart testing and scale with reliable manufacturing.

Prototyping Support

We offer custom prototyping services for new designs or application trials — ideal for R&D and low-volume testing.

Note: Prototyping is supported at an additional cost.

Mass Production Expertise

For serial production and large-scale supply:

- Competitive pricing

- Stable lead times

- Batch traceability

- Custom packaging & branding options available

We are equipped to scale from small runs to full-volume production with consistency and speed.

Quality You Can Trust

- ISO-Aligned Quality Systems

- Flexible Packaging Options

- In-House Testing & Inspection

- Material Certifications on Request

- Third Party Inspection reports on request at additional cost

Let’s Build a Better Seal Together

Whether you’re launching a new product or upgrading existing designs, Elplasto Innovations is here to deliver reliable, high-performance EPDM profiles that meet your goals.

Speak to our technical sales team for a quote, sample, or design collaboration.

Email: sales@elplasto.com

Web: www.elplasto.com

Phone: +91 85510 49350

Contact us today — we respond within 24 hours